Infrastructure

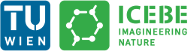

GP3 - Gas permeation pilot plantMobile standalone pilot plant for gas separation with a capacity of up to 6.0 m³(STP)/h.

Click for more information.

Pervaporation test unitLaboratory test bench for the analysis of single-stage pervaporation with a capacity of up to 200l/h.

Click for more information.

GP2 – gaspermeation test unitLaboratory test bench for the analysis of single-stage gaspermeation with a capacity of up to 0.5 m³(STP)/h and operating pressures ranging up to 13 bar(a).

Click for more information.

Gas mixing and analysis stationLaboratory gas mixing and analysis station with a capacity of up to 1.0 m³(STP)/h and operating pressures ranging up to 100 bar(a).

Click for more information.

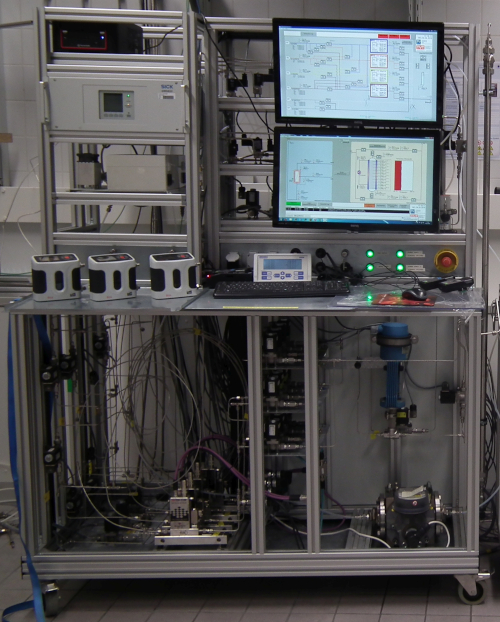

Hybrid membrane and adsorption gas separation facilityLaboratory scale hybrid gas separation facility with a capacity of up to 1.0 m³(STP)/h featuring a gaspermeation membrane step (operating pressure up to 100 bar(a)) and a multi-bed adsorption step (operating pressure between 0.5 and 20 bar(a)).

Click for more information.

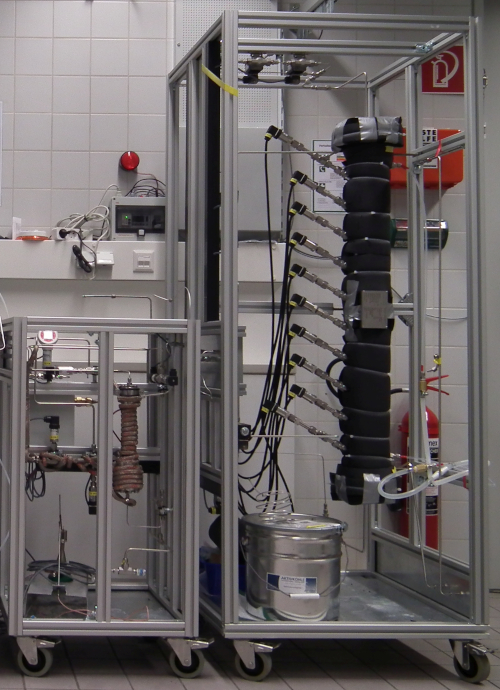

Thermostatized chamber for membrane module performance analysisFlexible and voluminous chamber for temperature-controlling membrane modules between 25 and 100°C.

Click for more information.

Pressure swing adsorptionLaboratory pressure swing adsorption setup with a capacity of 0.25 m³(STP)/h and operating pressures ranging up to 90 bar(a). Plant is currently under construction.

Click for more information.

RO/NF plantThree-staged pilot plant for pressure-driven membrane separation processes for liquid mixtures.

Click for more information.

SHOCOTEC – gas desulphurization unitPilot scale demonstration plant for a novel, in-house-developed process for desulphurization for energy-rich gases containing also carbon dioxide.

Click for more information.

Go to top